Today's Tidbit... A Very Fine Football, It Seams

Think about your typical football. Do you know how many leather sections or panels it has? Most people would say a football has four leather panels sewn together with four seams, and they would be correct, usually.

However, in the spirit of people who tinker trying to find ways to improve things, such as making a football more aerodynamic, there was a time when a few sporting goods companies produced footballs that did not have four sections.

You may recall a recent Tidbit about bootleg footballs that appeared in 1928 that did not meet the official specifications because they were slimmer than required. As a result, those balls were kept off the field from 1929 until 1934, when the rules were updated to make the official ball slimmer.

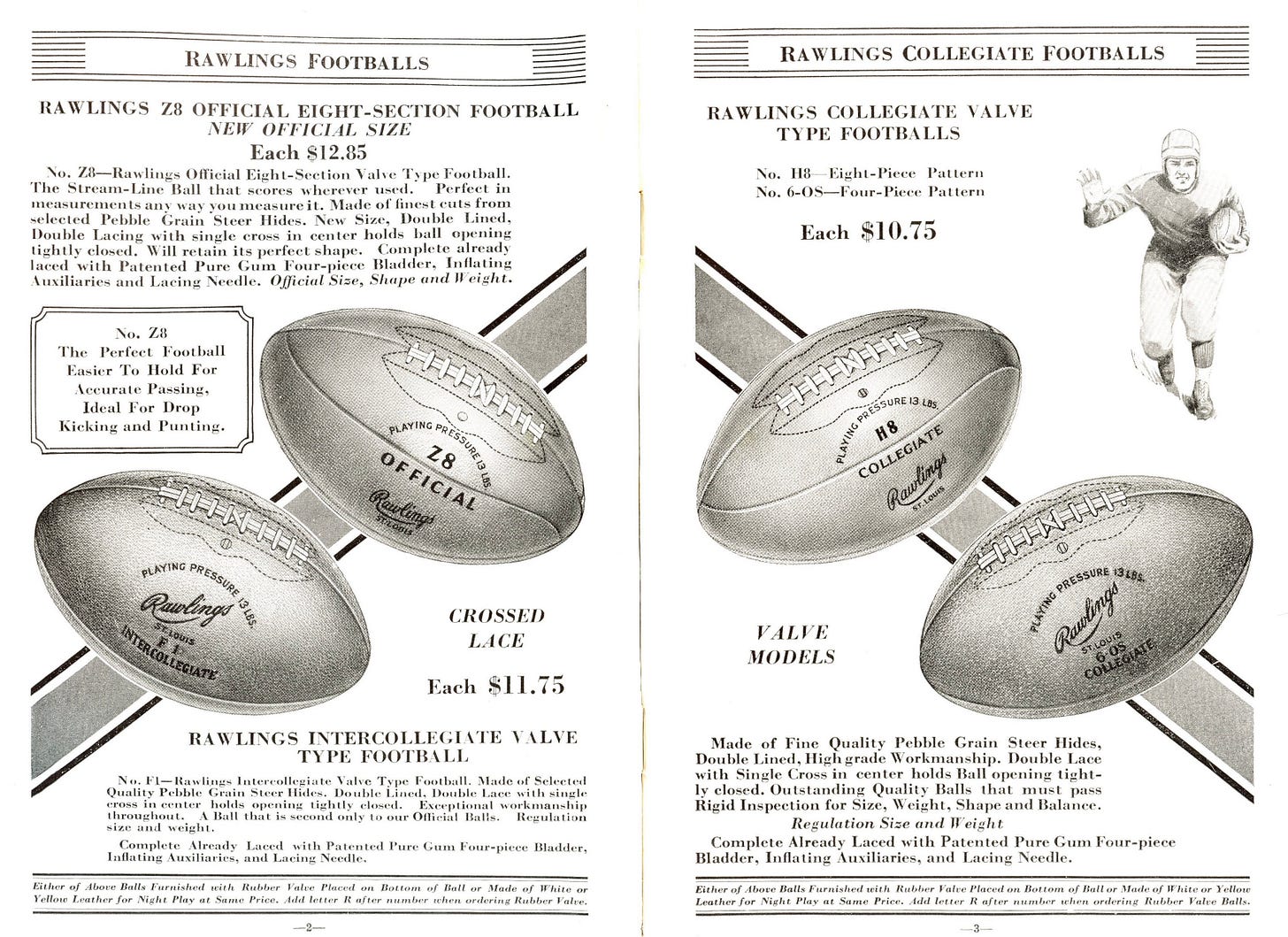

In the interim, sporting goods manufacturers looked for ways to make a regulation ball easier to throw accurately. Rawlings hit upon the idea of creating an eight-panel ball, perhaps believing the additional seams and their patterns would have a rifling on the ball as it flew through the air. The eight-panel ball popped up in news reports in 1931, and the 1932 rule book noted that a ball with more than four panels was legal if both teams agreed. (Click to enlarge)

Not to be outdone,

the thought leaders at Reach Wright & Ditson went the opposite direction by producing a two-panel ball, which they also believed flew through the air better than a four-panel ball. Not only that, the lack of a seam on the bottom of the ball made for more accurate punting, and by shifting the seams from the nose of the ball, they had a truer bounce when drop kicking.

Since very few of us have ever seen an eight- or two-panel ball, it appears they were not commercially successful and soon fell from the product list.

Football Archaeology is reader-supported. Click here to buy one of my books or otherwise support the site.